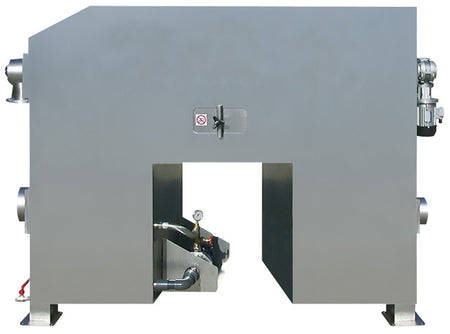

TEKNOBAG DRAIMAD®

Sludge Bag Dewatering Systems!

The TEKNOBAG DRAIMAD® system dewaters and bags sludge from water and effluent purification plants. The heart of the system is the special filtration sack made from water repellent material. The sacks are mounted on a special stainless steel frame, designed to give even sludge distribution. The system is electronically controlled from a programmable control panel, ensuring correct process operation. After a few hours operation the system will produce dry solids content of 15 - 30% depending on the type of sludge. The volume of dewatered sludge produced is dependent on the solid content of raw and dewatered sludge and, with raw sludge contents of 1% dry solids, one machine can treat up to 20 m³ per day.

Once the initial dewatering stage on the machine is finished, the sacks are removed and stored in the open. The special material allows dehydration of the contents of the sacks but prevents rainwater ingress. After two months storage, a cake of 50 - 95% dry solids content is produced. The package plants are fully automatic and include sludge conditioning, bag filling and draining cycles controlled by an integral control panel.

Various models are available with 2, 3, 6 and 12 sacks. Operation may be manual or automatic.

Complete Dewatering Package with 2, 3, 6 and 12 bags includes:

• Control Panel with automatic processor

• Polyelectrolyte Tank

• Polyelectrolyte Stirrer

• Polyelectrolyte Pump

• Sludge Pump

• Static Mixer

• Reaction Tank

• Construction: 304 Stainless Steel

• Pressurization package (P)

There are many different options available, please feel free to contact us for more information.

Sludge Bag Dewatering Systems!

The TEKNOBAG DRAIMAD® system dewaters and bags sludge from water and effluent purification plants. The heart of the system is the special filtration sack made from water repellent material. The sacks are mounted on a special stainless steel frame, designed to give even sludge distribution. The system is electronically controlled from a programmable control panel, ensuring correct process operation. After a few hours operation the system will produce dry solids content of 15 - 30% depending on the type of sludge. The volume of dewatered sludge produced is dependent on the solid content of raw and dewatered sludge and, with raw sludge contents of 1% dry solids, one machine can treat up to 20 m³ per day.

Once the initial dewatering stage on the machine is finished, the sacks are removed and stored in the open. The special material allows dehydration of the contents of the sacks but prevents rainwater ingress. After two months storage, a cake of 50 - 95% dry solids content is produced. The package plants are fully automatic and include sludge conditioning, bag filling and draining cycles controlled by an integral control panel.

Various models are available with 2, 3, 6 and 12 sacks. Operation may be manual or automatic.

Complete Dewatering Package with 2, 3, 6 and 12 bags includes:

• Control Panel with automatic processor

• Polyelectrolyte Tank

• Polyelectrolyte Stirrer

• Polyelectrolyte Pump

• Sludge Pump

• Static Mixer

• Reaction Tank

• Construction: 304 Stainless Steel

• Pressurization package (P)

There are many different options available, please feel free to contact us for more information.