Features

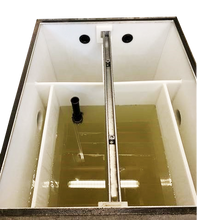

• Pre-built settling

• Protective cover for internal components

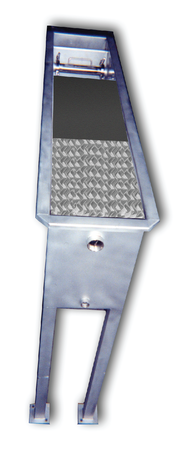

• Ability to incorporate a bypass line and acoustic and light alarm probes

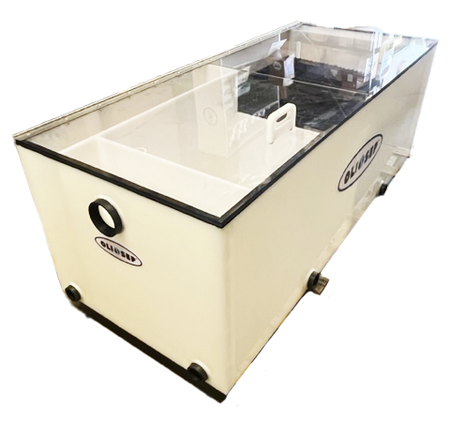

• High storage capacity of separated products

• High mechanical resistance and insensitivity to corrosion

• Easy installation and maintenance

• Completely sealed

• No energy consumption

• Low cost

• No odors (with adequate ventilation)

Characteristics

According to the legislation, oil/water separators must be installed in places where there is oily wastewater production, especially:

• Gas stations

• Fuel storage area and hydrocarbon in general

• Mechanical workshops

• Laundry areas

• Storage of scrap metal

• Parking

• Airports

• Garages

Operation

Operation of oil/water separators requires no energy. The separation is based on the density difference between products and is done by gravity. The heavier materials (mud, sand, etc.) sediment into the pre-sedimentation compartment while the lighter materials (oils) float to the surface and are collected in a reservoir.

Maintenance

The standards to be met are the regular inspection, with minimum quarterly frequency, of the following items:

• Thickness of the layer of oil

• Sludge accumulated at the bottom

• Coalescing filters

• Automatic shut-off valve

• Alarm device

| Part Number | Flow Rate L/min (USGPM) | Dimensions (LxWxH) |

| ER-840025 | 95 (25) | 610 x 711 x 610 mm, 24" x 28" x 24" |

| ER-840035 | 132 (35) | 762 x 864 x 762 mm, 30" x 34" x 30" |

| ER-840050 | 189 (50) | 914 x 762 x 813 mm, 36" x 30" x 32" |

| ER-840075 | 284 (74) | 1016 x 914 x 864 mm, 40" x 36" x 34" |

| ER-840100 | 379 (100) | 1067 x 1016 x 1016 mm, 42" x 40" x 40" |

| ER-840150 | 568 (150) | 1524 x 914 x 1168 mm, 60" x 36" x 46" |

| ER-840200 | 757 (200) | 1778 x 965 x 1219 mm, 70" x 38" x 48" |

For complete model information, view PDF brochure.