MONOBELT®

Sludge Dewatering Systems!

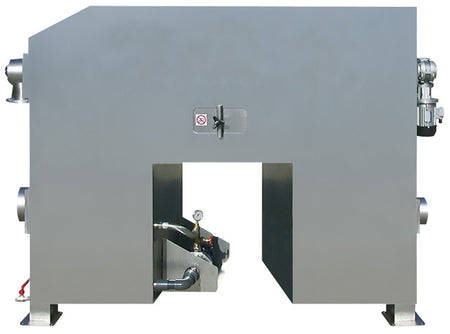

The MONOBELT® belt filter press is an entirely new patented design. It comprises two units, the pre-thickener and the sludge press. The prethickener performs the initial solid/liquid separation stage, taking sludge solids concentration from 0.5 - 3% up to 5 - 15%. The sludge press takes pre-thickened sludge and spreads it uniformly onto the main filter cloth via a series of baffles. Final dewatering occurs as the sludge cake passes between the perforated cylinder, which is covered with secondary cloth, and the main cloth. Discharged sludge cake can reach dry solids contents of 18 - 30%.

Max flow depends on the type of sludge and concentration of DS.

Sludge Dewatering Systems!

The MONOBELT® belt filter press is an entirely new patented design. It comprises two units, the pre-thickener and the sludge press. The prethickener performs the initial solid/liquid separation stage, taking sludge solids concentration from 0.5 - 3% up to 5 - 15%. The sludge press takes pre-thickened sludge and spreads it uniformly onto the main filter cloth via a series of baffles. Final dewatering occurs as the sludge cake passes between the perforated cylinder, which is covered with secondary cloth, and the main cloth. Discharged sludge cake can reach dry solids contents of 18 - 30%.

Max flow depends on the type of sludge and concentration of DS.