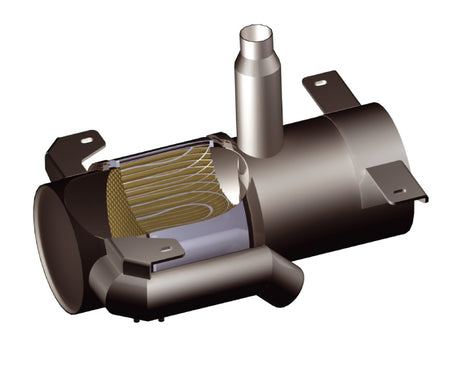

Catalytic converters utilize a precious metal diesel oxidation catalyst bonded to a monolithic, “flowthrough” catalyst core. The cores are made either of corrugated, high temperature resistant stainless steel foil or thin-wall cellular ceramics. In both cases, the cores are packaged into rugged stainless steel containers.

Conversion of diesel particulate matter is an important function of the modern diesel oxidation catalyst. Conversion of SOF may exceed 80%. Catalysts for heavy-duty applications incorporate sulfate suppressants to maximize their particulate matter performance. Total DPM conversions between 20 and 50% are typically observed. Low sulfur fuel is recommended for high DPM conversions.